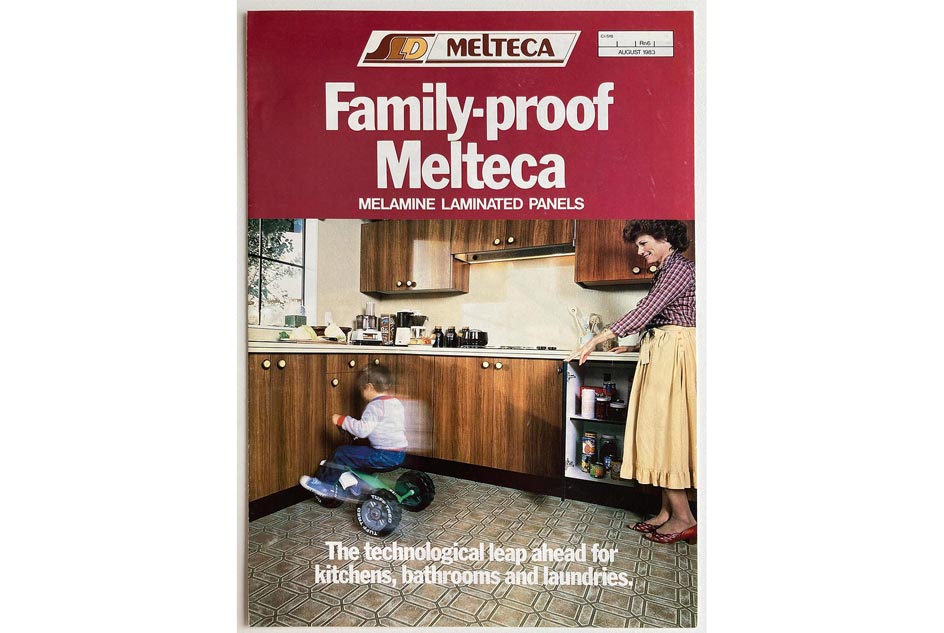

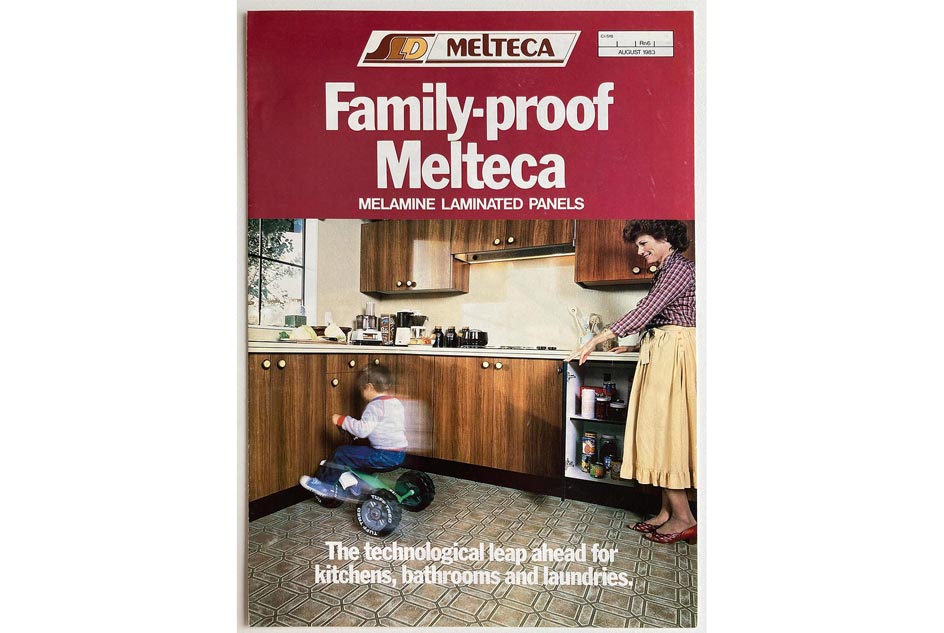

The first Melteca laminated board was pressed at the Laminex NZ board manufacturing plant in Hamilton back in 1983 and this year they are celebrating their forty year anniversary of continuous production. Bob Nordgren from JOINERS Magazine took the opportunity to speak with Laminex Plant Manager David Miles about the facility, his experiences there and the changes to date.

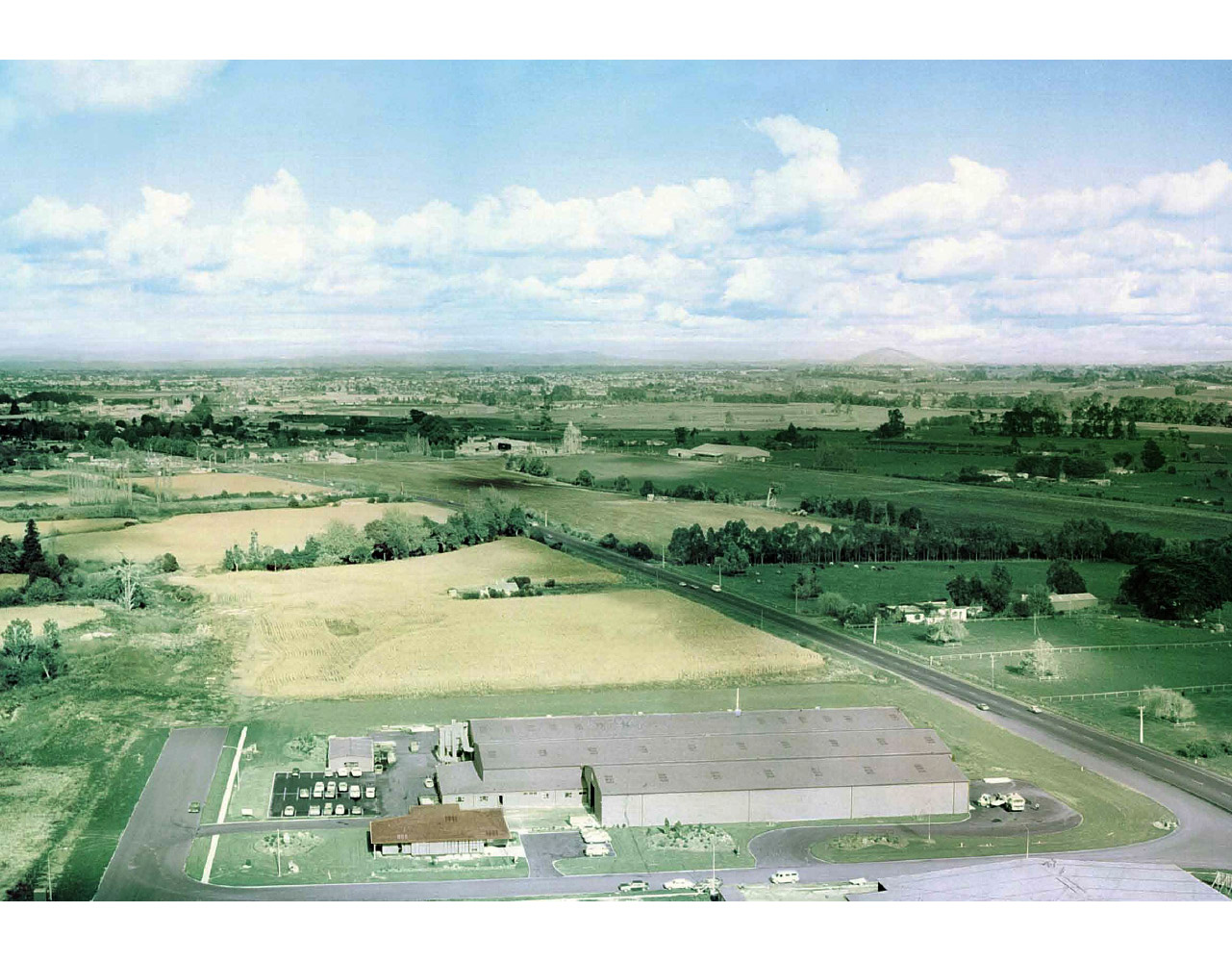

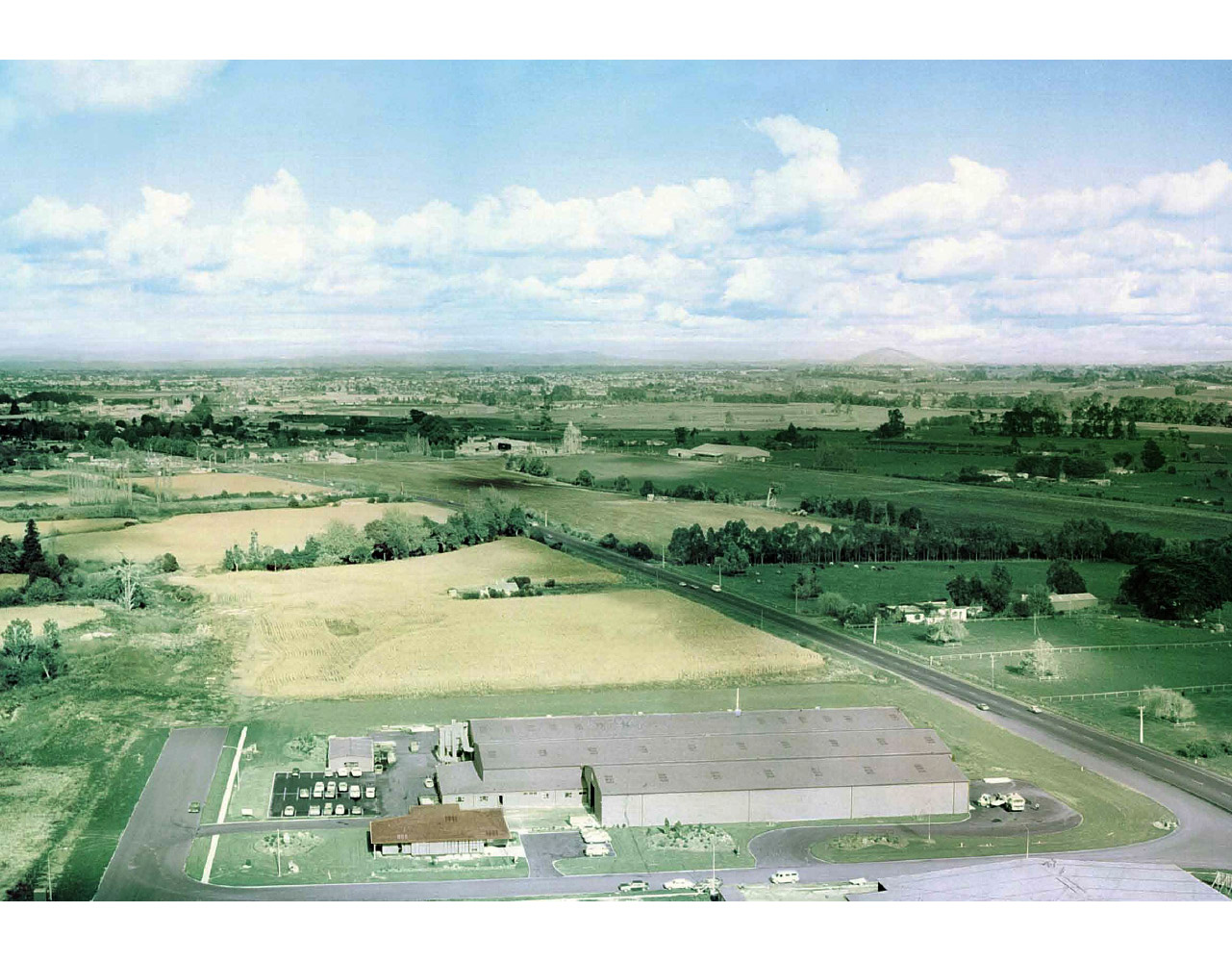

The Hamilton factory site has undergone considerable expansion since it first opened back in 1983. From the original building which had farmland all around, it’s now in an industrial hub and consists of some six buildings that include both the Melteca board production machinery and paper storage area, the samples production facility and adjacent board storage space.

The Melteca plant in 1983 when it was surrounded by farmland

The facility impresses with its size, safe and tidy appearance and almost understated efficiency. “We make all our Melteca board here and deliver to customers in New Zealand and overseas” comments David. “We can produce as little as one sheet to spec if need be and it is not uncommon to have several such sheets included in any particular order. We can take an order, press it often within a two day turnaround.”

The Melteca Plant today, in the middle of an industrial area with solar panels on the roof.

With some twenty years at the plant David has seen the operation’s growth first hand but what does he see as the most important changes in that time? “The biggie is the paper we use on the board. We used to buy the treated paper (impregnated with resin) from Germany but now we buy the paper only and do the impregnation here. This is significant as it now gives us total control of all materials we use and all processes involved in board production, this in turn gives us great production flexibility.”

I also wondered about the huge range of Melteca colours available. David comments “Although we produce a core number of colours all the time fashion of the moment often dictates the wider choices available. We have a relatively new part of the factory where we store a huge range of papers we can use.”

Part of the factory tour was to the facility where board samples are made. In talking to Karl Hutton, Samples Operator, I discovered some 2 million, yes that’s right million, samples are made at the factory and distributed every year. And who gets these samples? Well it turns out apart from customers a lot of kids get them to play with! Samples of off range decors are donated to playcentres.

“The Melteca brand is the best known for its quality and reliability. Over the years we have introduced many different plates (from which the paper texture and designs are made) including such brands as Puregrain and most recently the amazing Organic, a realistic wood grain texture, launched in November 2022.” says David.

The board produced is really safe these days as well. “We take real care with what we make to ensure it is safe for all concerned: those who make it and those who end up using it. It has the lowest level of formaldehyde achievable, FSC certification when pressed on standard MDF, and is Environmental Choice certified.” David says.

The very first Melteca brochure

The issue of sustainability has taken on a new meaning in recent times with the site’s six buildings having some 1362 solar panels installed and completed in September 2020. It was the largest rooftop install in New Zealand at the time. “These systems are indicative of the growth in commercial solar, both in size and number of systems installed. The project was headed by Vector Powersmart.” David explains. The factory operates 24/7 and has currently 54 staff . “The power generated will be recorded and displayed on monitors to show everyone and especially our staff how well the project works.” David points out. It is projected it will provide about 79% of the factory’s power annually. David adds “We hope to meter as many other aspects of the operation so that we can make further improvements as time goes by.”

From a more personal approach I asked David what motivates him some twenty years down the track to work at the factory. His answer was clear and heart felt “I like working with the people I work with. They are a good team, self sufficient and in a happy space.”

From humble beginnings some forty years ago the factory has grown to become very much a core element of Laminex NZ’s success. As to future changes we will just have to watch this space.

Written by Bob Nordgren, published in Joiners Magazine - March 2023 edition.