What’s the difference between high pressure laminate and low pressure laminate?

High-pressure laminate (HPL) and low-pressure laminate (LPL), often called melamine board, might look similar at first glance—but they’re quite different in how they’re made and where they’re best used. Understanding these differences is key to choosing the right material for your project. In this guide, we’ll explore their history in New Zealand, how they’re manufactured, and what makes each one suitable for different applications.

The first panels of Melteca rolled off the manufacturing line in Hamilton in 1983, redefining the New Zealand cabinetry scene. Today it’s available in a wide range of on trend colours and finishes and often specified alongside HPL.

HPL was introduced to New Zealand in the 1950’s under the brand name Formica and has been made by Laminex in Australia since the 1920’s. Today, Laminex Formica Laminate is a design-forward, high-performance surface.

Both offer strong design appeal, with 29 matching colours across the ranges, but what are the key material differences? Can you build a cabinet from Formica? Is Melteca suitable for benchtops? This guide will help you navigate those questions and choose the right product for the right purpose.

What’s the difference between HPL and LPL or Melamine board?

HPL refers to high pressure laminate and LPL refers to low pressure laminate, also known as low pressure melamine (LPM) or simply melamine board.

To create HPL, sheets of kraft paper are impregnated with resin, layered with decorative papers, and topped with an overlay paper for textural detail. Once dried and trimmed, the layers are fused under high pressure and heat to form a flexible 0.7mm sheet. This sheet can then be bonded to a substrate—such as medium-density fibreboard (MDF) or plywood—by a fabricator or joiner.

LPL is produced by bonding decorative paper that have been impregnated with melamine resin to a core material like MDF or particleboard in a press. The surface texture in the resulting panel is created during pressing by the pattern on the press plate. The Melteca factory operates with 5 different press plates for different finishes; Naturale, Pearl, Satin, Puregrain and Organic, which has a natural timber look.

Use Laminex Formica Laminate (HPL) for Kitchen Benchtops and Commercial projects

Laminex Formica HPL is absolutely the best choice for most medium-impact applications such as kitchen benchtops, where it is adhered to a solid substrate. HPL’s inherent durability and longevity also make it a great solution for commercial use such as reception desks and doors.

Use Melteca (LPL) for kitchen cabinets, wardrobes, furniture and wall lining

Melteca is a great choice for cabinetry, doors, panels and furniture. Being a prefinished panel makes it cost effective to manufacture, as it’s simply cut to size, finished with edging, and easily assembled into the final design. It’s robust and easy to clean, suitable for all but the most demanding commercial environments.

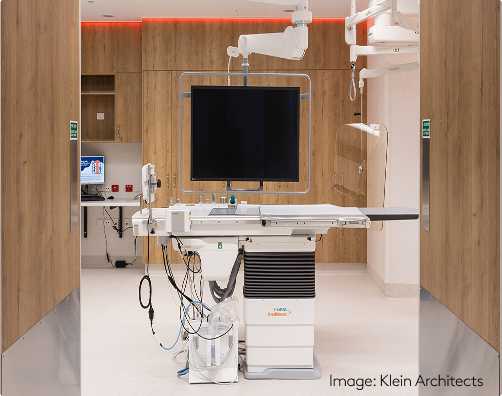

LPL panels are also well suited to larger-scale projects needing the right mix of installation efficiency, aesthetic appeal, durability and ease of maintenance – so LPL is often specified in retail, hotels, office-fit outs, and multi-residential projects.

While HPL can be used for all those applications as well, it needs first to be adhered to a rigid substrate, with implications for time and work involved in fabrication. This makes it less cost effective in those uses – except perhaps for projects that prioritise durability or flexibility such as curves.

With 29 matching decors available across Melteca and Laminex Formica Laminate, architects and design professionals can confidently combine HPL and LPL to suit different applications within a project. Click here to explore the full range of matching options.

Thoughtfully designed, and made to last.

With our HPL and LPM products, we draw inspiration from the colours and textures of nature, reflecting what we see in the diverse New Zealand landscape.

It’s also important to know that Laminex meets the expectations of New Zealand designers, fabricators and end users, with our over-arching commitment to sustainability in both manufacturing and product life. Melteca is based on Lakepine MDF, which is especially low in formaldehyde – in fact, it contains less than the average apple!